Cascade’s Custom Compounding

Our compounding process blends polymer chemistry, recycled content, and advanced additives to create resins ready for real-world applications. From automotive components to municipal infrastructure, every formulation is developed with precision and verified in our A2LA-accredited lab.

We can integrate recycled or bio-based feedstocks, colorants, fillers, and reinforcements to match your technical and environmental goals. Our team offers smooth production and repeatable quality at scale.

Industries We Serve

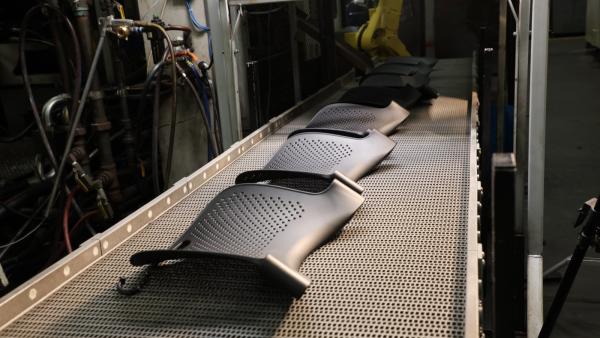

Automotive

Custom compounds for under-hood, interior, and structural components designed for weight reduction, impact strength, and long-term durability.

Office Furniture

High-quality engineered resins that maintain appearance and performance through years of use, with an ergonomic and aesthetic design.

Material Handling

Tough, reliable blends built for repeated loading cycles and exposure to heavy-duty environments.

Infrastructure

Compounded materials engineered to withstand temperature swings, UV exposure, and demanding outdoor conditions.

Waste & Recycling

Recycled-content resins and durable compounds that close the loop and turn old products into new, long-lasting components.

Why Choose Cascade?

Materials Expertise That Drives Innovation

Our in-house materials lab develops and tests compounds to meet precise mechanical, thermal, and environmental targets.

Commitment to Sustainability

We’ve built our business around the circular economy, integrating recycled and renewable materials wherever possible.

Proven Manufacturing Integration

Our plastic compounding work directly supports full-scale production so that every formulation runs seamlessly in your molding process.

Collaborative Development

We work side by side with customers, from design engineers to procurement teams, to refine materials that improve performance, reduce cost, and support sustainability goals.

Press Fleet Snapshot

-

Total machines: 37

-

Tonnage range: 165–9,000 tons

-

Part sizes: Up to 200 lbs (depending on material)

Molding capabilities: 2-shot, structural foam, and overmolding

Popular Materials We Mold

Recycled Base Materials

-

UBQ™

-

Hemp-based plastics

-

Post-consumer regrind

-

Field-sourced material from recycled carts

Polymer Types

-

Nylon

-

PP (Polypropylene)

-

HDPE (High-Density Polyethylene)

-

Acetal

Filled Resins

-

Glass-filled

-

Mineral-filled

-

Carbon-filled

Frequently Asked Questions

Plastic compounding is the process of blending base polymers with additives, fillers, and reinforcements to create materials with enhanced performance properties.

Yes. We regularly integrate post-consumer and reclaimed plastics into new formulations while maintaining consistency and quality.

By adjusting factors like stiffness, strength, or color, custom plastic compounding allows engineers to achieve better part performance, durability, and sustainability.

We use a range of additives, including colorants, UV stabilizers, flame retardants, lubricants, impact modifiers, and reinforcements like glass or mineral fibers.

Yes. Our materials lab can reverse-engineer or optimize your current resin for better flow, performance, or recyclability.

Yes. Each formulation is tested in our accredited lab to confirm performance and compliance with your specifications.

Blending combines ready-made materials, while compounding creates entirely new formulations by mixing polymers and additives under precise conditions.