Our Services

Polymer Compounding

We formulate high-performance compounds that balance strength, heat resistance, and processing efficiency, without compromising recyclability or cost. Our in-house A2LA-certified materials lab enables precise control over additive loading, color matching, and mechanical properties.

Custom Compounding

For projects that demand something unique, our materials team develops custom resin blends engineered to your product’s function and production method. We collaborate directly with your engineers to fine-tune mechanical, thermal, and aesthetic properties, ensuring consistent performance from pilot to full-scale production.

Industries We Serve

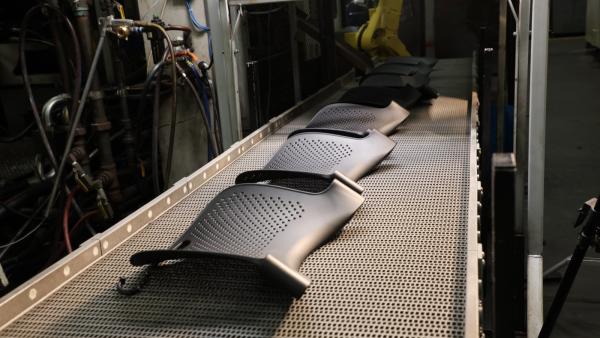

Automotive

Polymer compounds developed for structural, interior, and under-hood components where weight, impact performance, and durability matter over long service lives.

Office Furniture

Engineered materials designed to maintain strength, finish, and visual consistency through repeated use in commercial and institutional environments.

Material Handling

Custom blends built to handle repeated loading, abrasion, and exposure to demanding operational conditions.

Infrastructure

Polymer formulations engineered for outdoor use, supporting resistance to UV exposure, temperature shifts, and environmental stress.

Waste & Recycling

Recycled-content compounds that support circular material use while delivering the durability needed for long service cycles.

Why Choose Cascade?

In-House Materials Expertise

Our A2LA-certified lab provides direct access to compounding, formulation, and resin testing under one roof.

Sustainability Leadership

We’re advancing the circular economy through post-consumer regrind, UBQ™, hemp-based plastics, and other renewable materials.

Collaborative Engineering Support

Our materials engineers work directly with your team to align performance, cost, and environmental goals.

Proven Manufacturing Integration

We compound and mold within the same organization, ensuring consistency from formulation to finished product.

Press Fleet Snapshot

- Total machines: 37

- Tonnage range: 165–9,000 tons

- Part sizes: Up to 200 lbs, depending on material

- Molding capabilities: 2-shot, structural foam, and overmolding

Popular Materials We Mold

Recycled Base Materials

- UBQ™

- Hemp-based plastics

- Post-consumer regrind

- Field-sourced material from recycled carts

Polymer Types

- Nylon

- PP (Polypropylene)

- HDPE (High-Density Polyethylene)

- Acetal

- Filled Resins

Frequently Asked Questions

Yes. Our materials team can identify bio-based, recycled, or hybrid compounds that meet your product’s performance requirements.

We support automotive, furniture, infrastructure, waste management, and material handling industries, among others.

Yes. Our lab provides mechanical, thermal, and flow testing to verify performance before scaling to production.

We can develop color-matched and texture-specific compounds aligned with your brand or product line.

Yes. We collaborate with recyclers and raw material suppliers to source sustainable feedstocks and validate quality.

We offer flexible batch sizes for pilot runs and full-scale production, depending on material type and application.