Our Contract Molding Services

Contract molding is a full-service manufacturing partnership in which you outsource the design, tooling, and production of plastic components to an experienced molding manufacturer.

Cascade will act as an extension of your team, offering design assistance, materials expertise, large-tonnage production, and secondary operations to bring your ideas to market faster.

We handle the entire lifecycle, from engineering and tooling through production, assembly, and logistics, giving you complete control and confidence in every molded part.

- Reduced capital costs: No need to invest in presses, molds, or staffing.

- Faster time to market: Our engineering, tooling, and production teams operate under one roof.

- Access to expertise: Gain immediate support from materials engineers and manufacturing specialists.

- Consistent quality: ISO-certified systems, precision equipment, and sustainable production practices.

- Sustainability: Our materials lab formulates recycled and alternative resins, including UBQ™ and hemp-based plastics.

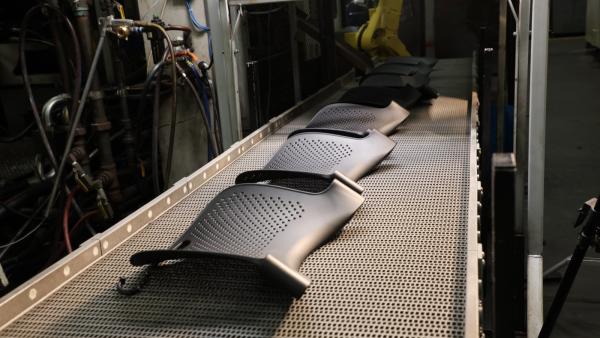

Automotive

Lightweight structural components that improve performance and efficiency.

Office Furniture

Durable, ergonomic parts that meet the demands of modern design and comfort.

Material Handling

Heavy-duty bins, pallets, and containers engineered for industrial use.

Infrastructure

Durable plastic components for utility, drainage, and construction applications that withstand heavy use and harsh environments.

Waste & Recycling

Reliable carts and components that support collection programs nationwide.

Why Choose Cascade?

Scale and Capacity

One of North America’s largest press fleets, capable of molding components up to 200 pounds, depending on the material.

Certified Quality

ISO 9001 and IATF 16949 certified manufacturing for consistent, traceable results.

Materials Expertise

Our A2LA-certified lab formulates and tests resins for optimal performance and sustainability.

Sustainable Production

Leaders in circular economy manufacturing using recycled and alternative materials.

Press Fleet Snapshot

- Total machines: 37

- Tonnage range: 165–9,000 tons

- Part sizes: Up to 200 lbs, depending on material

- Molding capabilities: 2-shot, structural foam, and overmolding

Popular Materials We Mold

Recycled Base Materials

- UBQ™

- Hemp-based plastics

- Post-consumer regrind

- Field-sourced material from recycled carts

Polymer Types

- Nylon

- PP (Polypropylene)

- HDPE (High-Density Polyethylene)

- Acetal

- Filled Resins

Frequently Asked Questions

We mold parts for automotive, furniture, material handling, agriculture, and infrastructure markets across North America.

Yes. We regularly use hemp-based plastics, UBQ™, and post-consumer regrind. Our materials lab can also help you reach recycled-content goals through custom resin formulation and polymer compounding.

We can mold components up to 200 pounds with press capacities ranging from 165 to 9,000 tons.

Yes. Our engineers collaborate on part design, mold flow analysis, and tooling recommendations to improve manufacturability and reduce cost.

We can support pilot runs and early-stage tooling to validate fit and performance before scaling.

Yes. We can coordinate trimming, assembly, labeling, and packaging based on your production goals.

We mold a wide range of polymers, including nylon, PP, HDPE, acetal, and filled resins for strength, stiffness, and temperature resistance.